Nonwoven Machine Guide

time2022/04/29

- Nonwovens are a booming industry. Widely used in packaging, household, industry, agriculture, medical and health, and other fields. The following introduces you to some knowledge related to non-woven machines.

Nonwovens are a booming industry. Widely used in packaging, household, industry, agriculture, medical and health, and other fields. But how do you buy a nonwoven machine to start this business? Today's guide will show you the facts behind the manufacturing process, machine spare parts, raw material feeds, and more. The following introduces you to some knowledge related to non-woven machines.

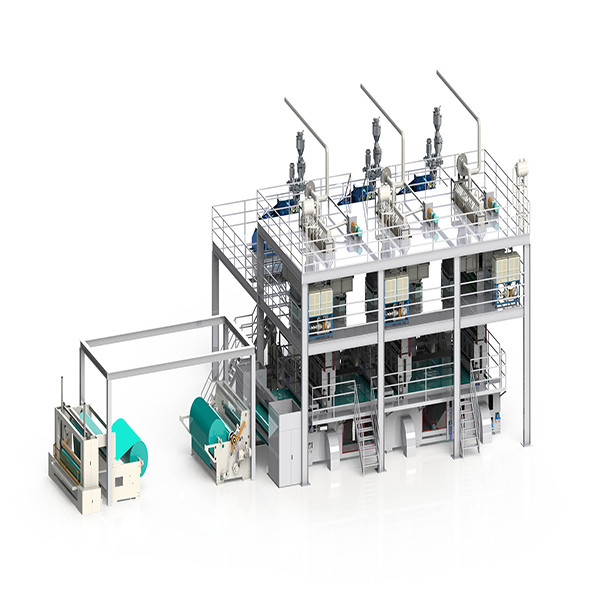

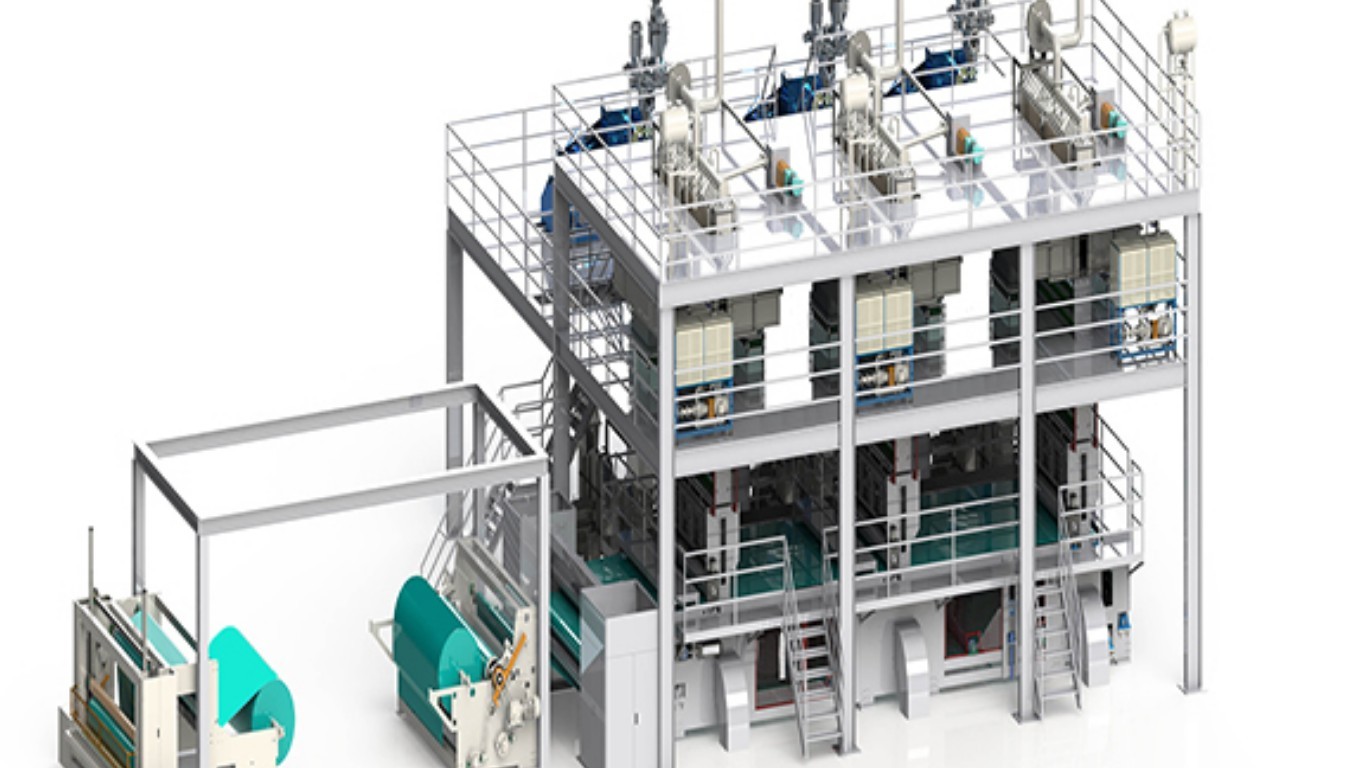

What is a non-woven machine?

Basically, a nonwoven fabric maker is an advanced machine that feeds, extrudes, sprays, and forms a web. Spunbond and meltblown are the most common processing methods in nonwoven equipment.

The spunbond production process is where polymers are melted and spun directly into nonwovens. The specific process is to heat, extrude and melt the polymer into a melt. The melt is ejected through a spinneret. The filaments of the spinneret are cooled and drawn into a large number of fine fibers by the airflow. The filaments are then joined into a web by hot rolling.

The meltblown process is based on high melt index polymers. The polymer is extruded, heated, and melted into a high-temperature melt. The melt ejected from the spinneret is blown into extremely fine fibers by the high-temperature and high-speed hot airflow. The filaments are then gathered into a web on a web former.

Where are the non-woven machines used?

Take a moment to think about the occasions where you use nonwovens. In fact, it has become an important part of our lives today.

Applications for nonwovens range from simple uses such as shopping bags to more complex uses such as baby diapers. Without a nonwoven fabric maker, we would miss an important aspect of our lives. In general, the non-woven fabrics produced can be used in household products, medical and hygiene products, packaging, clothing, and industrial and agricultural fields.

Nonwoven machinery parts

The non-woven production line consists of small mechanical equipment. They play different roles in the manufacture of nonwovens. Some core equipment determines the quality of the cloth.

1. The dosing equipment is the entrance of the raw materials.

2. The extruder processes the raw material into a melt. At the same time, the recycling machine collects and extrudes the non-woven scraps into a melt.

3. The filter device removes impurities in the PP melt. Automatic candle filters are the most common on the market. It is designed to be cleaned without turning off the power.

4. The metering pump controls the supply speed of the PP melt flow.

5. The spinneret is one of the most important components in the spinning box. The melt from the extruder is turned into filaments in the spinning machine.

6. The stretching machine container stretches up and down. They are used for wire drawing.

7. The net former is the carrier for making the filament into the net. 8. Hot rolling is another important part of non-woven equipment. It is used to bond webs by pressure and heat

8. The winding machine affects the running speed of the machine. High-speed wind turbines that can operate at 300-600 m/min are generally recommended.

9. The standard widths of non-woven fabrics are 1600mm, 2400mm, and 3200mm. The slitter can cut fabrics with a minimum width of 100mm.

Raw materials

The raw materials of spunbond and meltblown nonwoven machines refer to auxiliaries such as PP, PET, PLA, and color masterbatch. They are sent to the litter box in a certain proportion. Raw materials are a large expense for a nonwoven machinery project. You have to prepare for one month of use.

.

How to choose a non-woven machine type?

When you know the basic information about non-woven machines, it is time to choose the right machine type for your product. This usually depends on your product and daily needs. There are four types of non-woven machines: single S, SS, SSS, and spunmelt composite lines. For example, single S is a non-woven fabric used for packaging non-woven bags. If you are not sure how to choose the right nonwoven fabric-making machine, you can contact us to help you choose.

AZX is a professional custom nonwoven machine manufacturer. We always adhere to the business philosophy of "everything is based on user value". Bringing together the top technical team, excellent management team, and professional service team. With an independent R&D center and a number of patented technologies, it provides high-quality products and services to the world.