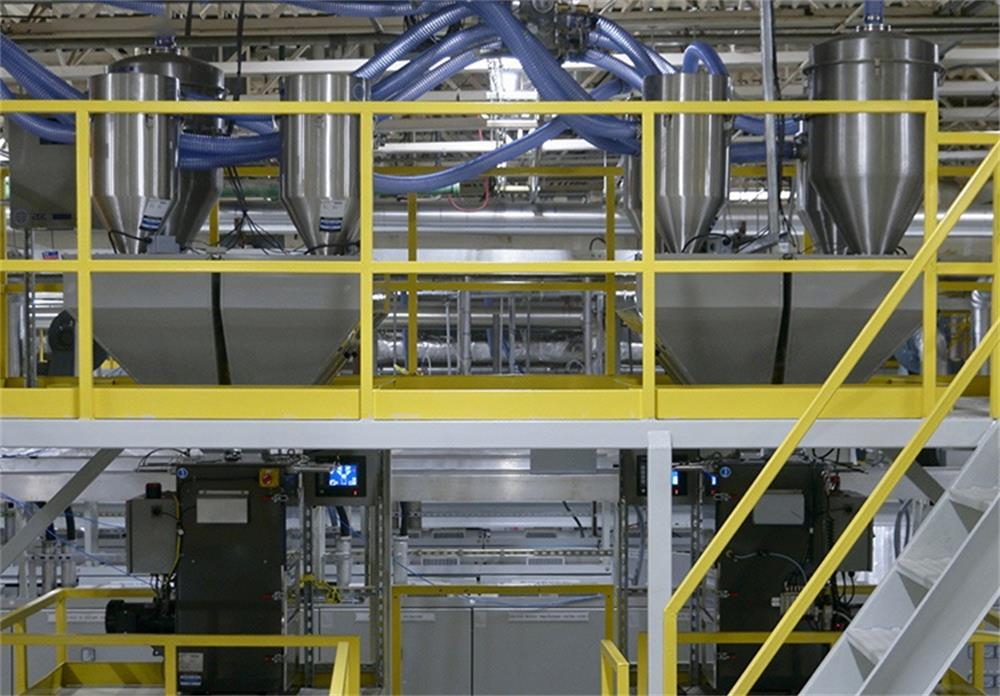

The Reason Why the Meltblown Non-woven Fabric Equipment is Equipped with a Meltblown Fabric Heater

time2022/02/18

- Melt-blown cloth heater is an electric heating device in which a heating tube is installed in a cylindrical heat preservation container to heat gas. This article will specifically introduce the reasons why meltblown non-woven fabric equipment needs a meltblown fabric heater.

Melt-blown cloth heater is an electric heating device in which a heating tube is installed in a cylindrical heat preservation container to heat gas. The non-woven fabric heater has the characteristics of fast heating speed, good heat preservation performance, and high heating temperature.

The heater is composed of the main body and the control system. The heating element is made of stainless steel pipe as the protective sleeve, and the high-temperature resistance alloy wire crystalline magnesium oxide powder is formed by the compression process.

The control part adopts an advanced digital circuit integrated circuit to trigger, high back pressure thyristor, etc. to form an adjustable temperature measurement and constant temperature system to ensure the normal operation of the electric heater. You can better understand the reasons why melt blown fabric heaters are used in melt blown non-woven fabric equipment by understanding the technical characteristics of the following melt blown fabric heaters.

Technical characteristics of melt blown cloth heater

1. It can obtain a higher working temperature under lower operating pressure.

2. The melt-blown cloth heater has high thermal efficiency, which can reach more than 95%, and the temperature control accuracy can reach ±1℃.

3. The equipment is small in size and flexible in installation. It should be installed near the heating equipment with high power.

4. Fast thermal response, high-temperature control accuracy, and high comprehensive thermal efficiency.

5. The melt blown cloth heater has a wide application range and strong adaptability. It can be used in explosion-proof or ordinary occasions. Its explosion-proof grade can reach B and C grades, and its pressure resistance can be 20Mpa. And the cylinder can be installed vertically or horizontally according to user needs.

6. The heating temperature is high, and the design maximum working temperature can reach 650℃, which is not available in general heat exchangers.

7. The melt blown cloth heater has a long life and high reliability. It is made of special electric heating materials, and the design power load is more conservative.

Because of the higher air pressure of the melt jet drafting system, a fan with a higher output pressure is required. Roots blowers, screw blowers, screw compressors, etc. are all commonly used drafting blowers.

The air gap of the melt blown assembly is small and the system resistance is large. In order to maintain a certain flow rate, an air compressor with more energy consumption and higher pressure must be selected as the drafting air pressure source.

If you want to know more about meltblown non-woven equipment components after reading the above, you can get a comprehensive solution by contacting me.

As a professional non-woven equipment supplier, we have accumulated rich R&D and manufacturing experience in this field. We have a professional production team and strict quality inspection system, which can control the quality of products in all aspects. At the same time, we will provide thoughtful one-stop service and effective solution technology according to the actual needs of customers. If you want to buy our meltblown non-woven equipment, please contact us immediately!