Basic Knowledge of Meltblown Nonwoven Technology

time2021/07/30

- The development and upgrading of meltblown non-woven fabric technology allows high-quality meltblown non-woven fabrics to be applied in more fields. This article will specifically introduce the basic knowledge of meltblown nonwoven technology.

Meltblown nonwoven fabric technology is often used in melt-blown non-woven fabric equipment. The main function is to produce melt-blown non-woven fabric products with filtering performance, but there are still many people who do not know this technology very well. The following is the basic common sense of meltblown nonwoven technology.

Technical characteristics of meltblown non-woven fabrics

The melt blowing method is to directly form a web from the polymer, and the polymer melt extruded by the screw extruder is blown by high-speed and high-temperature airflow or other means (such as centrifugal force, electrostatic force), so that the melt stream is extremely stretched The very fine short fibers are then gathered on a web forming drum or web curtain to form a web, and finally self-adhesive to be reinforced to make a non-woven fabric.

The specific process is to melt the polymer chips through a screw extruder, and extrude them from the spinneret holes of the spinneret after being filtered. Under the jet of high-speed hot air, they are stretched to form extremely fine Short fibers, these short fibers are absorbed and condensed on the mesh curtain. Because the threads have not been cooled, they can still maintain a higher temperature after they are condensed into a web.

Through the adhesion between the fibers, the fiber web can be strengthened to form a melt blown cloth. It can be further strengthened by hot-rolling bonding method as required.

At present, most of the raw materials used in the melt-blown method are polypropylene, but polyester or polyamide can also be used. It may be higher. The spinning temperature, blowing airflow and speed used for raw materials with different melt indexes are changed accordingly to ensure that the thread is fully drawn and improve the quality and performance of the fiber.

The raw materials of vinegar that can be used in the melt blown method are polypropylene, polyester, polyethylene, polystyrene and polyphenolamine, etc. The most commonly used is polypropylene. Because this method uses high-pressure hot air drafting, it is best to use raw materials with low temperature control and good flow properties. That is, the use of polymers with a higher melt index is beneficial to increase production and reduce energy consumption. The melt index (MFI) of polypropylene is generally above 18.

Meltblown process flow

Polymer feeding-melt extrusion-fiber formation-fiber cooling-netting-reinforcement into cloth.

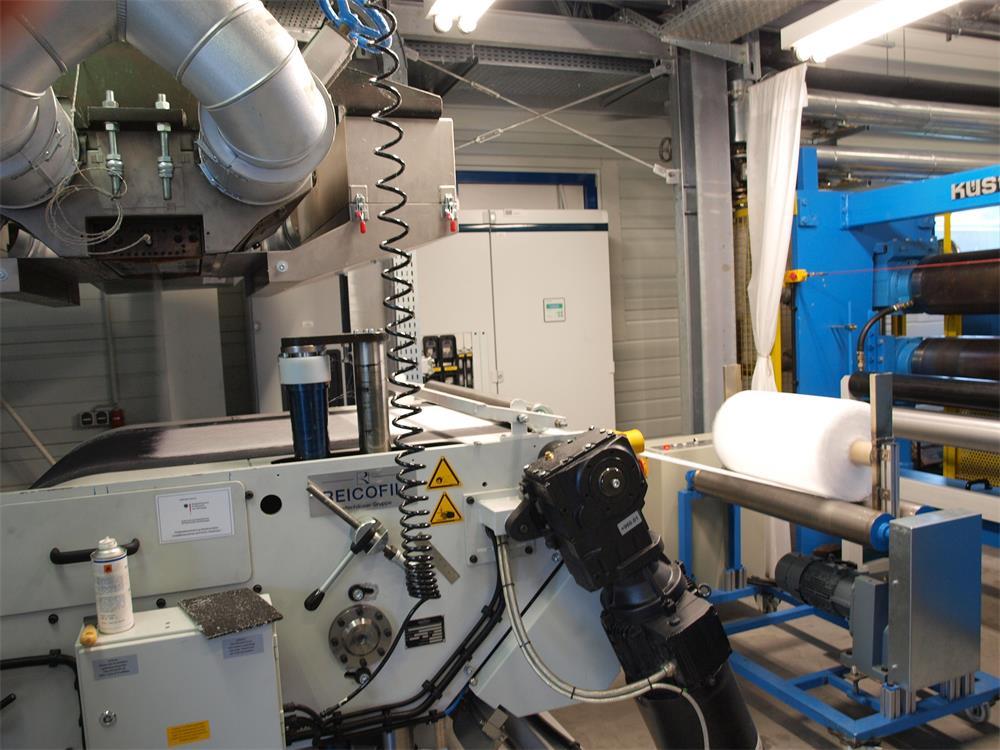

The whole set of equipment for the production of meltblown non-woven fabrics is composed of the main engine, heating system, lubrication system, hydraulic system, cooling system, and electrical control system. The host is the core of the whole set of equipment, which mainly includes feeding system, screw extruder, filter screen, spinning assembly, spinneret die, receiving net system, and winding mechanism.

The melt-blown non-woven fabric equipment produced by AZX has applied this melt-blown non-woven fabric technology well. The melt-blown non-woven fabric products produced can filter substances with smaller diameters and have an ultra-fine filtration effect. They are often used as Breathable barrier material. If you want to know more about meltblown non-woven fabric technology after reading the above content, you can get a comprehensive solution by contacting us.

As a professional manufacturer of non-woven equipment, we have won praise and trust from many customers with our excellent technology and high-quality products. We put the needs of our customers first, the equipment we produce meets strict standards, and we also have a professional quality inspection system to strictly control the weight of each link of production. If you are interested in our meltblown non-woven equipment, please contact us immediately!